The brewing process

HOW IS THE BEER MADE?

--------------------------------------------------

1. MALT

Grains cannot be processed directly from the land in the brewery. They must first be malted in a malt house. This process has four steps: cleaning, soaking, sprouting and kilning (drying). For flavor variation, malt is caramelized or roasted. Light malts are used for the blond beers and for the dark beers extra dark malts are added.

2. SCRAPED MALT

At the beginning of the brewing day, the malt is scraped. Scrap is the crushing of the malt grains so that the starch is released, but the husks (husks) remain intact. This crushing is done in a scrap mill with two rollers between which the grains are crushed.

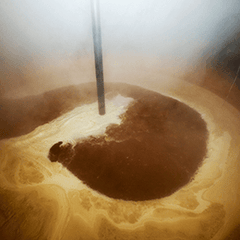

3. DUMPING THE MALT

When the brewing water in the brewing kettle has reached the right temperature, the scrapped malt is poured into the kettle. This 'batter' is then heated in steps. During this process, the starch is converted into different types of sugars. The different temperatures are necessary because enzymes are active at different temperatures. These enzymes convert starch into fermentable sugars. The fermentable sugars are converted into alcohol by the yeast cells and the unfermentable sugars are left behind as 'sweetness' in the beer.

4. FILTERING THE BATTER

The mash is filtered in the lauter tun. The husks of the malt grains form the filter bed. The wort (sugar-containing liquid) in the mash descends through this bed and is collected. At the same time, the filter bed is sprayed with fresh brewing water to wash out any remaining sugars. The amount of sugar in the wort determines the alcohol percentage of the final beer. Therefore, the brewmaster controls the sugar concentration. The filtration is stopped when the desired sugar concentration is reached.

5. BEER IN THE BACK

Any liquid that has passed through the filter is pumped directly into the boiler. Then the cooking can take place. This liquid is called 'wort'.

NOBLE HOP VARIETIES

There are different hop varieties, of which only the female hops are used. Each hop variety has its own character. By adding these in different proportions, the brewmaster can give each specialty beer its distinctive smell and taste. The used hop flowers are compressed into pallets, large granules, which are easy to store and dose.

6. ADD THE HOP VARIETIES

The wort that has been pumped to the brew kettle is brought back to the boil there. During the cooking, the brewmaster adds the different hops. At the beginning of the cooking for the bitterness and at the end of the process for the smell.

7. COOKING THE WORT

After adding the hops, the brew is brought to a boil. During cooking, bitter substances are released that dissolve in the beer. Moreover, heating sterilizes the beer and flakes out the proteins, which would otherwise lead to a lot of turbidity.

8. TOP FERMENTATION BEER

The fermentation takes place at room temperature. The different yeast strains give Hoop beers their distinctive taste. After fermentation, lagering also takes place. This is at about 0 degrees Celsius and takes 2 to 3 weeks. This is where the right flavors are released and aftertaste that you don't want disappear. The lagering is under pressure and takes place in the same tanks as the fermentation. That is why they are also called yeast/lager tanks.